Fluorine gas generation

About fluorine gas generation

Carbon electrode for fluorine electrolysis (FE-8) is a high-density, high-strength material that uses special raw materials. Toyo Tanso will make proposals for the suitable use of FE-8 electrodes, from the shape of the electrodes to the conditions under which the electrodes are used in the electrolytic cell.

Our carbon electrode for fluorine electrolysis (FE-8) has the following features and exhibits excellent performance in the operation of a fluorine gas generating electrolytic cell. In addition, we can make various technical proposals such as optimal conditions for using electrodes and operating conditions for the electrolytic cell (measures against heat generation / corrosion in the electrolytic cell).

Feature

- Uses a raw material exclusively for fluorine electrolysis to suppress the anode effect (* 1)

- High strength and hard to break

- High critical current density (* 2) improves electrolysis efficiency

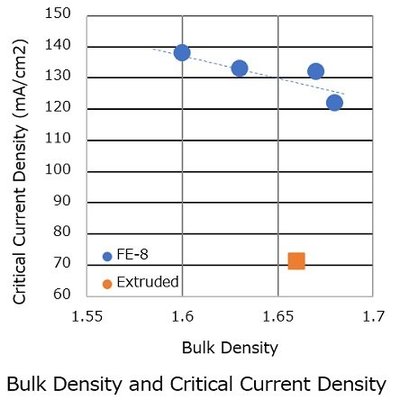

FE-8 has a critical current density that is about twice that of extruded material.

FE-8 has approximately twice the critical current density of extruded material. By using this electrode, fluorine can be generated more efficiently. (In-house experiment results)

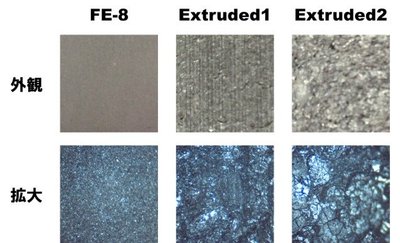

Our FE-8 is a high-density, high-strength material made by CIP (Cold Isostatic Press) molding of fine powder raw material. During fluorine electrolysis, it suppresses the increase of impurities in the fluorine gas and electrode collapse due to particle separation.

Representative characteristic value

| Material | Bulk density | Hardness | Electricaly resistivit |

Flexural strength |

Ash content |

|---|---|---|---|---|---|

| Mg/m3 | HSD | μΩ・m | MPa | mass % | |

| FE-8 | 1.64 | 108 | 49 | 69 | 0.17 |

The above values are typical characteristics, not guaranteed values.

About the manufacturing method and application of fluorine electrolysis

In 1886 Henri Moissan (France) succeeded in isolating fluorine for the first time by electrolysis of HF. After that, fluorine electrolysis was industrialized in the 1940s. At that time, extruded electrode was the mainstream, but if the electrode cracks or the anode effect occurs, it will be necessary to replace the electrode. This replacement work is hard work, and the generation of fluorine stops during this work, so electrodes that can be used stably for a long period of time are required.

Main applications of fluorine gas

1.Gasification of high melting point inorganic substances

2.Semiconductor etching / cleaning gas

3.Special gas (alternative CFC, insulating gas)

4.High-performance resin (PTFE, PFA, ETFE, etc.)

5.Battery application (graphite fluoride, LiPF6)

In 1886 Henri Moissan (France) succeeded in isolating fluorine for the first time by electrolysis of HF. After that, fluorine electrolysis was industrialized in the 1940s. At that time, extruded electrode was the mainstream, but if the electrode cracks or the anode effect occurs, it will be necessary to replace the electrode. This replacement work is hard work, and the generation of fluorine stops during this work, so electrodes that can be used stably for a long period of time are required.

Main applications of fluorine gas

1.Gasification of high melting point inorganic substances

2.Semiconductor etching / cleaning gas

3.Special gas (alternative CFC, insulating gas)

4.High-performance resin (PTFE, PFA, ETFE, etc.)

5.Battery application (graphite fluoride, LiPF6)

By using FE-8, the electrolytic cell can continue electrolysis stably for a long period of time and can efficiently generate fluorine. Please contact us for electrode usage conditions.

Related Link

Communication Service Menu

YouTube Channel

YouTube Channel

Carbon product FAQ

Carbon product FAQ

Carbon ABC

Carbon ABC