Electrical discharge machining (EDM)

Electrical discharge machining (EDM)

Toyo Tanso provides a wide range of graphite materials for EDM.

Toyo Tanso provides a wide range of graphite materials for EDM, available for rough machining to finishing.

Graphite electrode materials for EDM are widely used as EDM electrodes in the manufacturing process of various molds, such as plastic molds, die-casting molds, forging molds, and press molds, from large to small precision ones.

Compared to copper electrodes, graphite electrodes have excellent machining performance and do not produce burrs, making it possible to increase speed in both machining and EDM.

The TTK grade developed by our company is characterized by its micron-order ultrafine particle structure. This makes it an excellent choice for electrode cutting, wire EDM, and die-sinking EDM. It also enables sharp edges, reduced electrode wear, and improved EDM surface roughness and surface accuracy, which were not possible with conventional graphite materials.

As a new lineup, We developed EDM electrode for cemented carbide(ISEM-43C), and started selling it in 2022. Compared with our conventional materials, ISEM-43C allows for reduced variations in wear in electric discharge machining, making it ideal for stable machining.

The material also has both Graphite's excellent machinability and copper's electrical discharge machining performance.

In this way, graphite electrode materials for EDM can greatly contribute to cost reduction and quality improvement as well as lead time reduction in a wide range of markets from mold manufacturing to parts processing.

Features

- Light-weight

- Good workability enable to speed up machining

- Lower burrs

- Enable ultraprecision machining and micromachining

Advantages of Graphite electrode (Compared with copper)

Advantage in electrode machining process

1. No burr generation

No burrs are generated during graphite machining, eliminating the need for deburring work required with copper. Therefore, automation is possible.

2. Reduced machining time

Compared to copper, graphite has a cutting resistance of about 1/5 to 1/10, which provides good machinability and reduces machining time.

In addition, it can be processed with small-diameter end mills and integrated electrodes can be manufactured.

3. Light weight and easy handling

The weight of graphite is about 1/5 of copper, making it easy to handle.

4. Capable of fine shape machining

Graphite has lower cutting resistance than copper, and residual stress generation can be suppressed, so it is less deformation even in fine shapes.

Advantages in EDM

1. Shorter processing time/strong>

Graphite has excellent heat resistance and can carry a higher current than copper, which can reduce the machining time by 30-50% or more.

2. lower wear

Due to the excellent heat resistance of graphite, wear caused by heat during discharge is lower than that of copper.

3. Reduction of discharge time by integrating electrodes/strong>

Graphite, which can be machined with an integrated electrode, can reduce EDM time compared to copper (which requires a split electrode).

4. Less thermal deformation

The coefficient of linear expansion of graphite is about 1/4 that of copper, which means that it is less likely to be deformed by heat and has excellent dimensional accuracy.

Graphite material for Ultra fine EDM electrodes : TTK series

The TTK grade developed by Toyo Tanso has an ultra-fine particle structure of micron order.

This feature enables sharp edges, reduced electrode wear, and improved surface roughness and surface accuracy in electrode cutting, wire EDM, and die-sinking EDM, which could not be achieved with conventional graphite materials.

- 1. Enable micromachining : No bent even with ultra-fine pin such as Φ0.0019 inch

- 2. Reducing Machining Time : Comparing to metal, good workability enable to speed up machining

- 3.No Burrs : Since no burrs are generated during cutting, can be used for EDM immediately after machining

- 4. Less Deformation : Graphite electrodes do not deform due to cutting resistance or heat during EDM like metal, so accurate EDM processing is possible

New Product EDM electrode for cemented carbide(ISEM-43C)

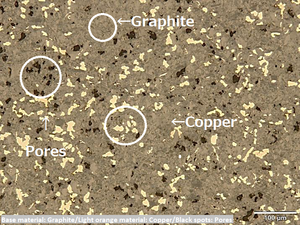

Copper graphite material for cemented carbide (ISEM-43C) is a composite material consisting of isotropic graphite pores impregnated with copper.

Characteristics

Our proprietary processing technology ensures that the graphite is uniformly impregnated with copper, which has the following characteristics compared to our conventional materials.

For electrode cutting process

・Easy to machine (machinability)

During electric discharge machining

・Low electrical resistivity improves processing efficiency

・Arc generation can be suppressed even at high output, shortening EDM processing time.

Typical characteristics

| Grade | Bulk density | Hardness | Resistivity | Flexural strength | Thermal conductivity | Coefficient of thermal expansion |

|---|---|---|---|---|---|---|

| g/cm3 | HSD | µΩ・m | MPa | W/m・K | 10-6/K | |

| ISEM-43C | 2.75 | 52 | 2.2 | 75 | 187 | 5.5 |

| TTK-55 (Toyo Tanso Gr material) |

1.80 | 73 | 15.3 | 63 | 86 | 5.6 |

| TTK-5 (Toyo Tanso Gr material) |

1.78 | 80 | 15.5 | 80 | 80 | 5.7 |

*The figures above are typical values, and are not guaranteed.

Lineup of graphite materials for EDM

Toyo Tanso offers a wide range of EDM materials, from rough processing to precision processing, to meet the various needs of our customers.

Comparison of Grades by Electrode Wear and Machining Speed

Physical Properties (Typical)

Grade Microstructure Bulk Density(Mg/m3) ISEM-8 1.78 63 ISO-63 1.78 1.78 1.77 18.0

Hardness(Shore)

Specific Resistivity(μΩm)

13.4

76

15.0

TTK-5

80

15.5

TTK-9

90

1. The figures above are typical values, and are not guaranteed.

2.For the size, please refer to the property data of isotropic graphite.

YouTube Channel

YouTube Channel

Carbon product FAQ

Carbon product FAQ

Carbon ABC

Carbon ABC